Omega

Single-stage axially split volute casing pump for horizontal or vertical installation, with double-entry radial impeller, mating flanges to DIN, EN or ASME.

Main Applications

-

Waterworks

-

Desalination plants

-

Pressure boosting

-

Water transport

-

Service water and cooling water for power stations and industry

-

Irrigation pumping stations

-

Drainage pumping stations

-

Fire-fighting systems

-

Shipbuilding

-

District heating systems and district cooling systems

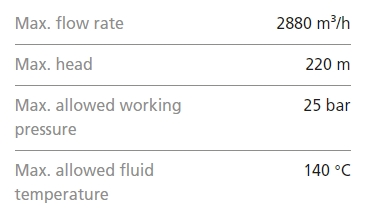

Technical Data

Benefits

-

Low maintenance costs:

-

Fast and easy to install thanks to self-centring components (upper casing part, rotor, casing cover)

-

Materials resistant to corrosion and abrasion

-

Smooth operation with low vibration levels

-

Replacement and spare parts fit several pump sizes

-

-

Long service life:

-

Sealed and dry shaft

-

Short bearing distances and a short shaft

-

Optional impeller wear rings

-

Replaceable shaft protecting sleeve

-

-

High operating reliability:

-

Rigid shaft without threads between the bearings

-

Generously sized bearings (Lh10 = 100,000 hours)

-

Reliable sealing thanks to solid casing split flange

-

Double-entry impeller for axial thrust balancing

-

Double volute design

-

-

High flexibility:

-

Drive can be positioned to the left or right of the pump

-

Shaft sealed by gland packing or mechanical seals

-

Various horizontal and vertical installation options

-

Flanges to DIN or ASME

-

-

Excellent efficiencies and NPSH values:

-

Computer-optimised impellers

-

Large impeller inlet diameters for optimum suction behaviour

-

Cost-effective replacing of casing and impeller wear rings

-

Vortex-free intake elbow with low energy losses

-

Impeller trimmed to match the specified duty point

-

Several hydraulic systems per pump size

-