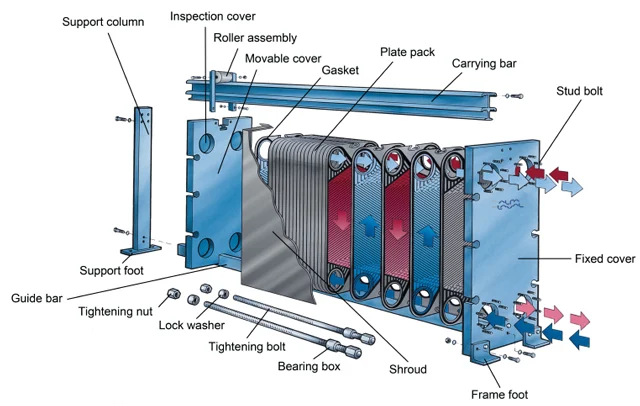

There’s a common misconception in the industry that all gasketed plate-and-frame heat exchangers are the same, no matter the brand. However, there are quite a few design features that can have a huge impact on your operation. The features highlighted below are important components to look for in a GPHE, and when combined, these features offer extensive benefits, including:

- Reduced installation, maintenance and spare parts costs

- Reduced energy costs

- Decreased downtime

- Higher production output

- Increased staff safety