Etanorm SYT

Horizontal volute casing pump in back pull-out design, single-stage, with ratings and dimensions to EN 733, radially split volute casing with integrally cast pump feet, replaceable casing wear rings, closed radial impeller with multiply curved vanes, single mechanical seal to EN 12756, double mechanical seal to EN 12756, drive-end bearings: rolling element bearings, pump-end bearings: plain bearings, with magnetless KSB SuPremE motor (exception: motor sizes 0.55 kW / 0.75 kW with 1500 rpm are designed with permanent magnets) of efficiency class IE4/IE5 and PumpDrive variable speed system; ATEX-compliant version available.

Main Applications

-

Heat transfer systems

-

Hot water circulation

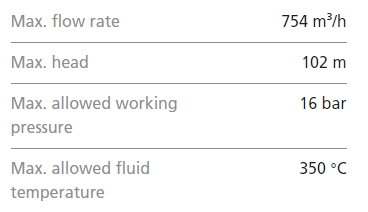

Technical Data

Benefits

-

Designed to deliver reliable operation with mineral and synthetic thermal oils up to 350 °C

-

Maximum operating reliability ensured by KSB single mechanical seal and KSB double multi-spring mechanical seals in tandem arrangement as well as quench systems tailored to any application

-

Safety barriers: Optimised contour ensures reliable removal of leakage at the mechanical seal; additional shaft seal ring, durable grease-packed bearings, confined sealing elements and effective heat barrier

-

Reliable venting during pump operation by patented KSB VenJet® technology

-

Individual requirements are met with maximum efficiency, and operating costs are reduced: impeller trimming, variable speed operation / intelligent control by KSB frequency inverters and KSB motors up to IE5, maximum hydraulic pump efficiency and low NSPHreq

-

Wide range of applications through compliance with EN PN16 and ASME, ATEX-compliant version, carbon and SiC/SiC plain bearings, marine version to DNV GL and version with fan impeller for efficient cooling

-

The “cracked-joint” design of the coupling hubs enables straightforward assembly and dismantling of the coupling. The double Cardan coupling compensates shaft offset.

-

Continuous leakage monitoring by innovative KSB Leakage Sensor. Predictive maintenance avoids unscheduled downtimes.

-

Vibration, pressure and temperature measurement connections provided as standard. Sensor kit can be ordered together with the pump.